Offshore Wind Turbine Inspection

UVision makes it possible to perform underwater wind turbine inspections with our visual 3D scanner

Underwater inspection of offshore wind turbines is crucial for ensuring their structural integrity and operational efficiency. These inspections help in identifying potential issues early, such as damage or wear from marine environments, thus preventing costly repairs and downtime.

Regular underwater assessments contribute to the longevity of turbines and support the sustainability of renewable energy sources by maximizing their output and reliability. At UVision, our dedication to underwater inspections is the heartbeat of our mission, driving everything we do.

CPS Inspection

The Cable Protection Systems or other parts of offshore wind turbine foundations can be easily and effectively scanned with the same effort it takes to make a video wind turbine inspection with an ROV. The 3D model gives an overview of the CPS and its surroundings making it easy to spot signs of unwanted oscillation, excessive biological growth or other factors which can result in a shorter lifetime if remedial action is not taken.

Foundation inspection

Inspecting the concrete foundation of offshore wind turbines is vital for maintaining structural integrity, especially in the face of biological growth. The marine environment fosters the growth of organisms like barnacles and mussels, which can lead to increased weight, drag, biodeterioration and potential corrosion, especially in splash or tidal zones. Regular wind turbine inspections help identify and address these issues, preventing compromised foundations.

ROV inspection

In this customer case a Chasing M2 Pro Max and UScanner were used to perform the scan. The advantages of this set up include:

Hand portable – easy to transport

Operated by just two people – minimal manpower required

No operational vessel or crane needed – can be deployed from the foundation, minimising cost

Rapid scanning – a windmill foundation scan take just 20 minutes

Advantages of Using a Pole Mounted Device

The use of a pole-mounted device for wind turbine inspection offers significant advantages. Shallow water wind turbine foundations can now be inspected efficiently by walking around the bottom platform, holding the pole without entering the water.

This method drastically reduces cost and increases inspection speed, allowing a single team to scan many more wind turbines a day. They can be delivered via a small Crew Transfer Vessel, instead of a larger support vessel with ROV crane and extended crew. The full kit with scanner, computer, power and cable fits into a ruck sack and can be set up in a few minutes.

This approach is not only more efficient but also safer, reducing the risk associated with traditional diving methods.

Why Use a Visual 3D Scanner for Offshore Wind Turbine Inspection?

Photorealistic Detailing

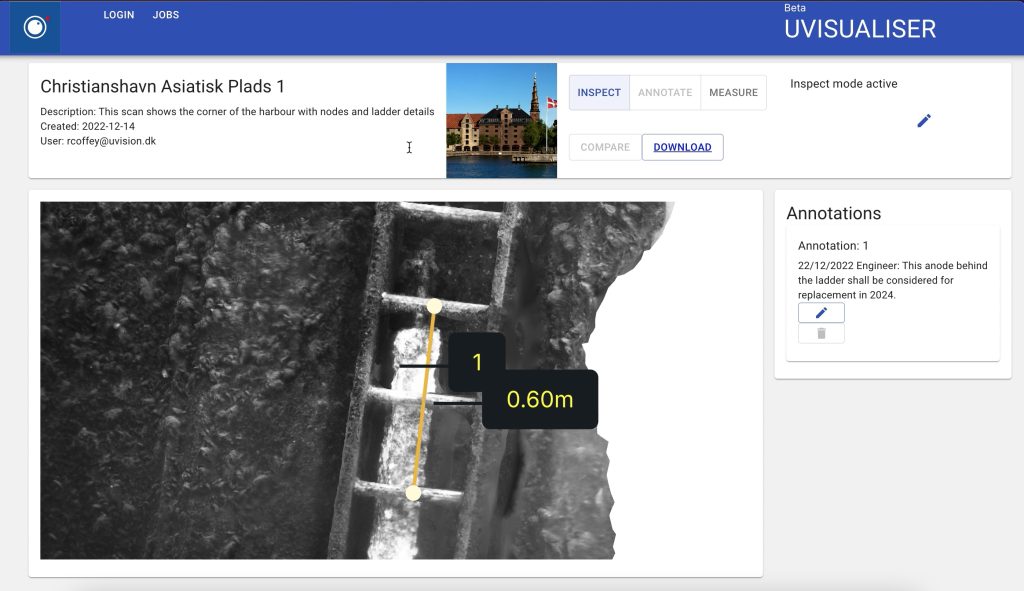

Visual 3D models capture the intricate details of underwater structures in high resolution, providing a comprehensive view that aids in identifying defects or damage with unparalleled clarity. This photorealistic detailing ensures no critical issues are overlooked.

Millimeter Precision

These models offer precise measurements up to the millimeter, enabling accurate assessments of structural integrity and wear. This level of precision is crucial for planning maintenance, repairs, and ensuring the long-term safety and efficiency of offshore wind turbines.

Cost-Effective Monitoring

With the ability to generate detailed and accurate models quickly, visual 3D scanning reduces the need for frequent diver deployments, cutting down on inspection costs and time. This efficiency makes it a cost-effective solution for ongoing infrastructure monitoring.

Underwater 3D Scanner

Starting at €13.900 ex.VAT

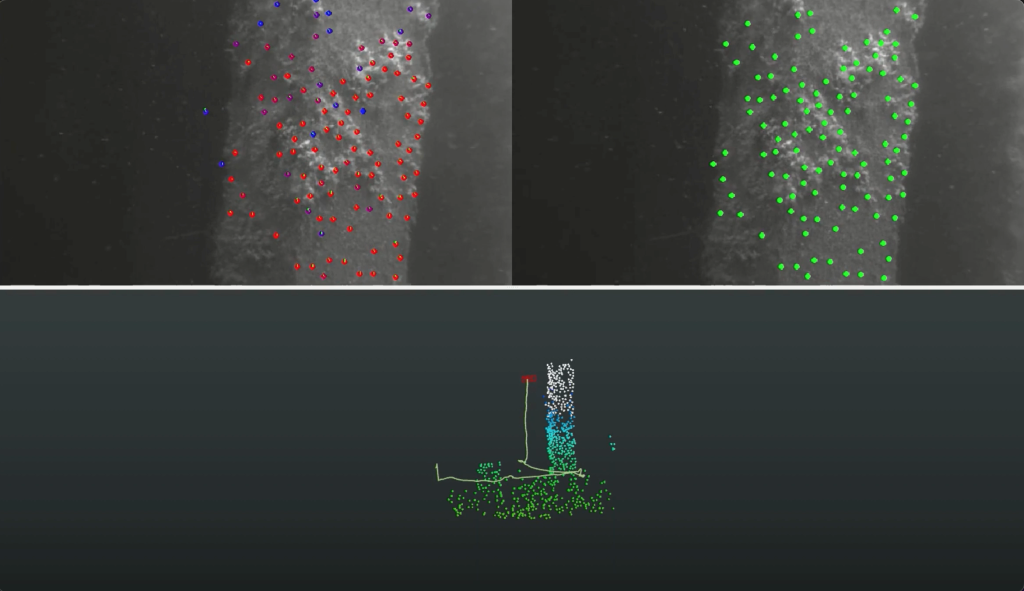

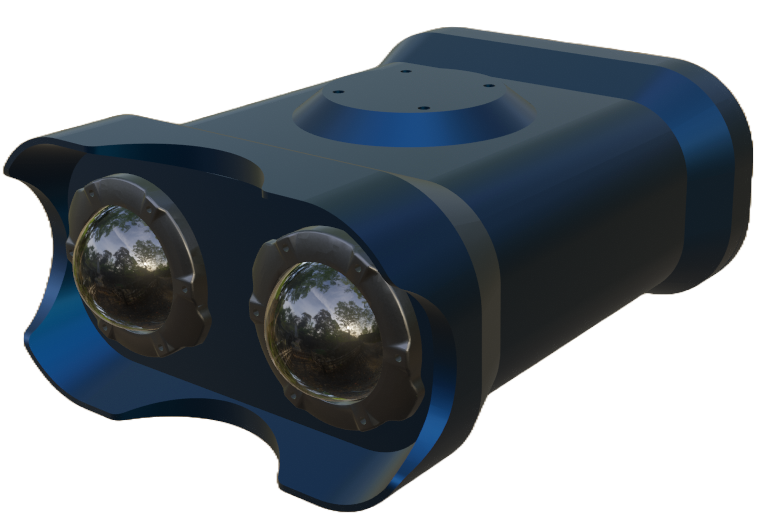

The UVision 3D Scanner is a cutting-edge device that seamlessly combines high-quality still images and positioning data for efficient point cloud generation and photogrammetry.

The global shutter stereo camera captures all pixels at the same moment – as opposed to rolling shutter which reads pixels sequentially – securing the most accurate image is captured. The dome ports minimise distortion at the periphery of the field of view, maximising image quality.

The device is small and light giving it various mounting options. The aluminum casing is corrosion resistant and designed for 300m depth.