Bridge inspection made easy

Underwater Insights with UVision

Assessing river scour

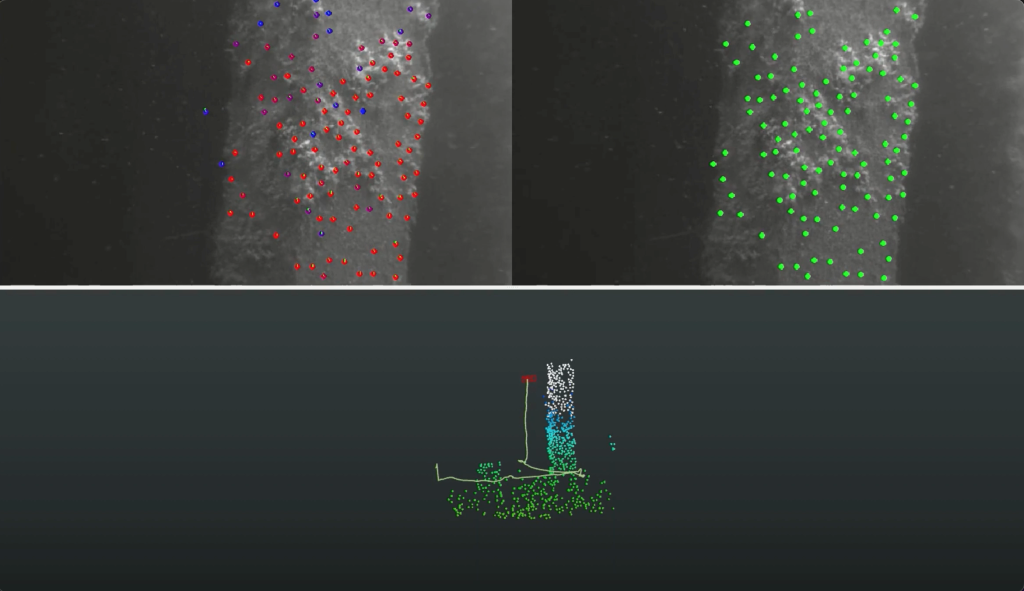

The UScanner, equipped with advanced 3D modeling technology, provides a powerful tool for detecting, documenting, and evaluating the extent of river scour. Using precise scanning and imaging techniques, it creates detailed 3D models of bridge foundations and surrounding riverbed conditions. These models enable engineers to closely examine areas vulnerable to scour and accurately assess their severity.

Decision making

By monitoring changes over time, the UScanner allows for proactive maintenance planning, helping decision making regarding when repair or reinforcement is necessary. This transparent and data-driven approach aids in prioritizing investments, ensuring that resources are directed to the most critical infrastructure, and minimizing the risk of unexpected failures. Ultimately, the UScanner helps enhance bridge safety, reduces long-term repair costs, and helps safeguard public safety and transportation networks.

Mounting Flexibility

The scanner is small and light, giving various mounting possibilities depending on the needs of the job.

ROV Mounted

The scanner can be mounted and easily integrated to any ROV and even smaller ROVs. It can function as a main camera or used as an additional sensor.

Pole Mounted

For inspections close to the water side the scanner can be simply mounted on a pole with its own lights and power supply. It can also be used in combination with a Virtual Reality (VR) headset!

Handheld

A diver can document their inspection using the scanner by hand. We can provide different grips depending on preferences.

Why Use a Visual 3D Scanner for Bridge Inspection?

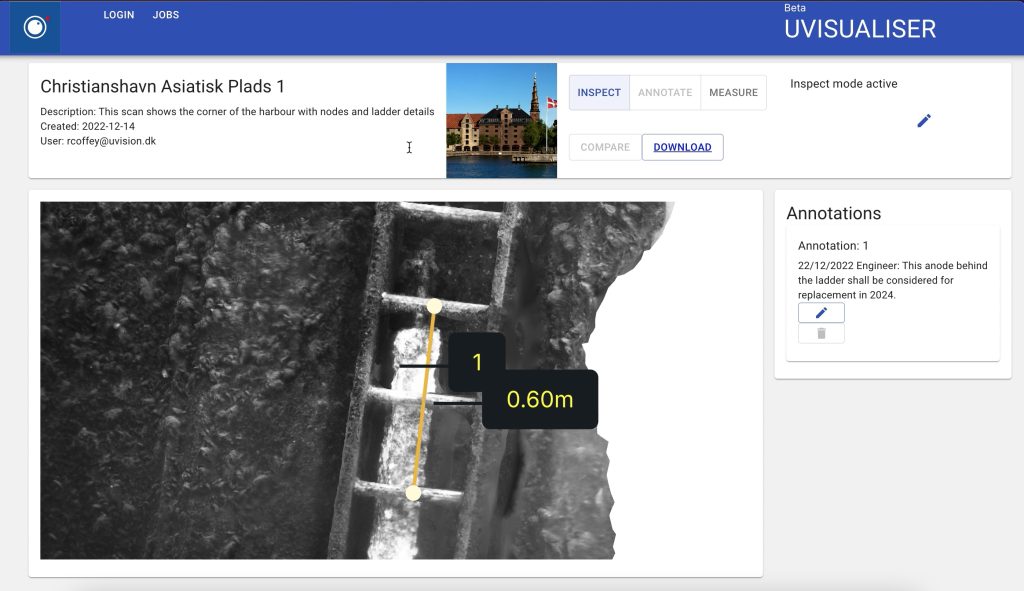

Photorealistic Detailing

Visual 3D models capture the intricate details of underwater structures in high resolution, providing a comprehensive view that aids in identifying defects or damage with unparalleled clarity. This photorealistic detailing ensures no critical issues are overlooked.

Millimeter Precision

These models offer precise measurements up to the millimeter, enabling accurate assessments of structural integrity and wear. This level of precision is crucial for planning maintenance, repairs, and ensuring the long-term safety and efficiency of offshore wind turbines.

Cost-Effective Monitoring

With the ability to generate detailed and accurate models quickly, visual 3D scanning reduces the need for frequent diver deployments, cutting down on inspection costs and time. This efficiency makes it a cost-effective solution for ongoing infrastructure monitoring.

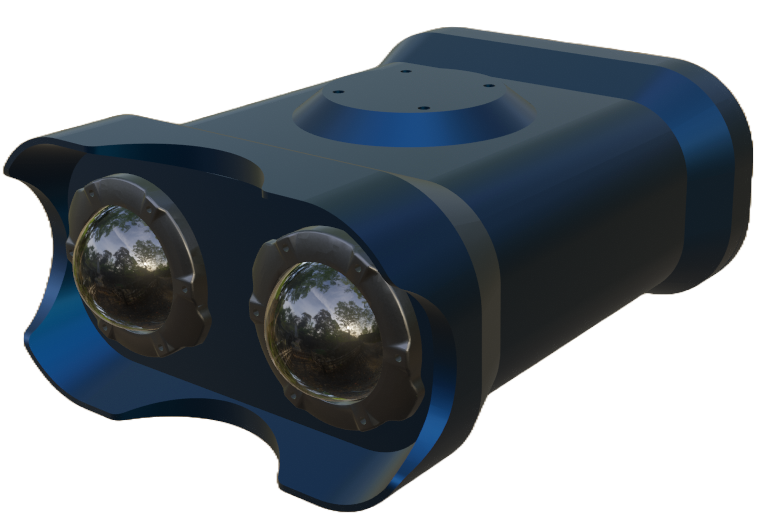

Underwater 3D Scanner

Starting at €13.900 ex.VAT

The UVision 3D Scanner is a cutting-edge device that seamlessly combines high-quality still images and positioning data for efficient point cloud generation and photogrammetry.

The global shutter stereo camera captures all pixels at the same moment – as opposed to rolling shutter which reads pixels sequentially – securing the most accurate image is captured. The dome ports minimise distortion at the periphery of the field of view, maximising image quality.

The device is small and light giving it various mounting options. The aluminum casing is corrosion resistant and designed for 300m depth.