Canal lock inspection

UVision makes it possible to perform lock inspection without draining the water

Minimise disruption

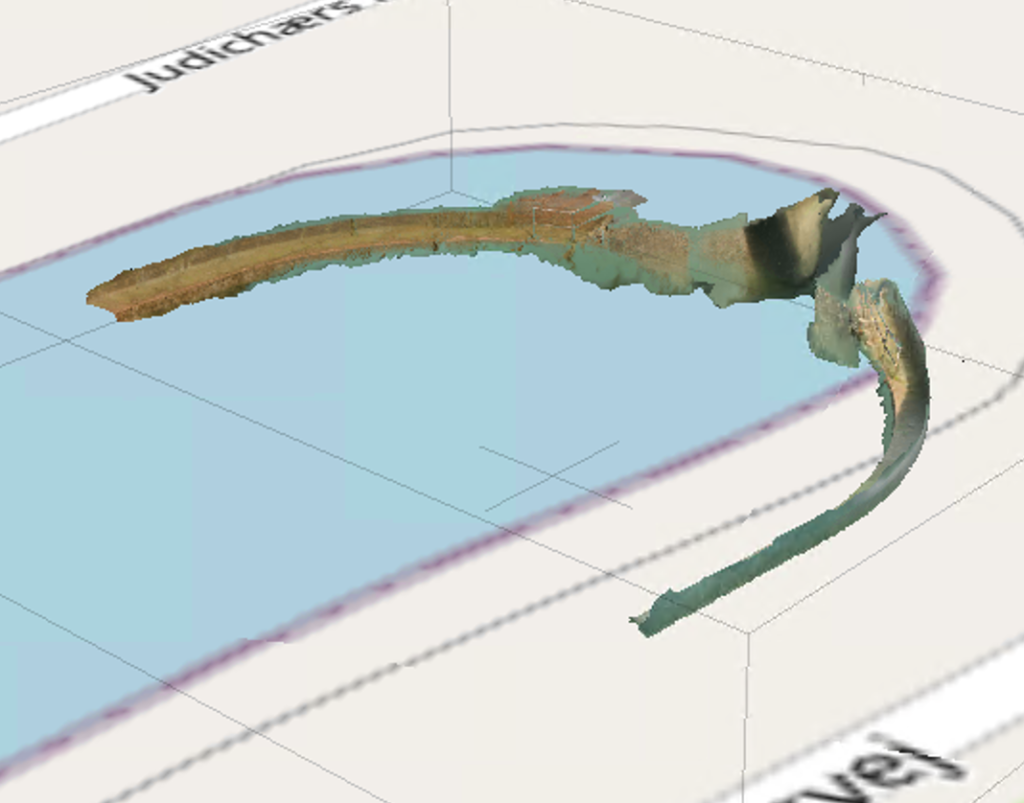

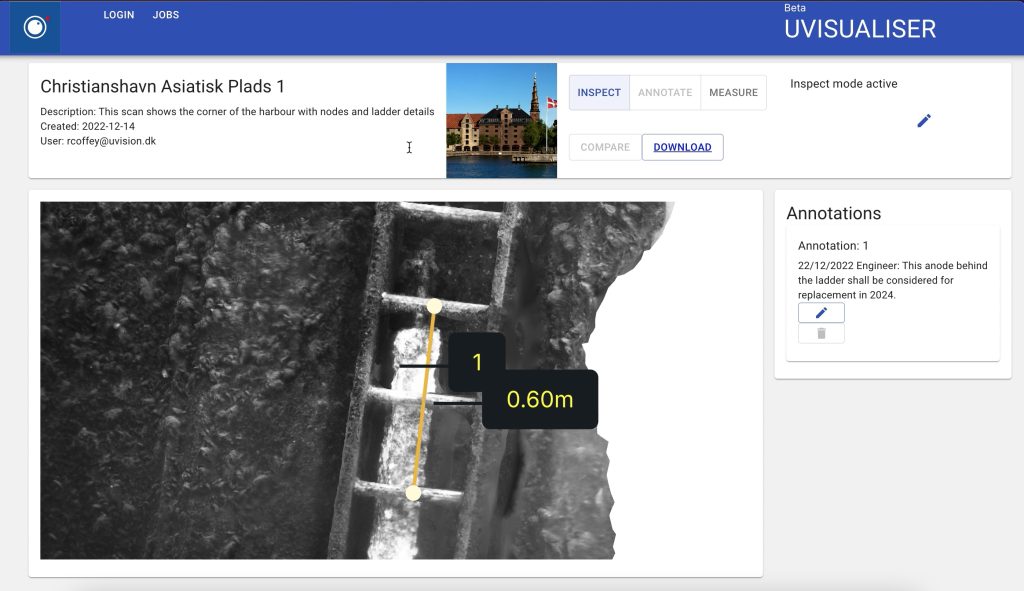

The high resolution photorealistic 3D model of the walls and gates of the lock provide and alternative way of inspection.

The 3D model itself can be inspected and based on this it can be decided if repairs are needed. If not it will save the cost, time and disruption of performing the drain down.

If it is concluded that repair work is required then the repair team can be much better prepared, reducing the disruption time and increasing effectivity.

Accurate documentation

Global Positioning

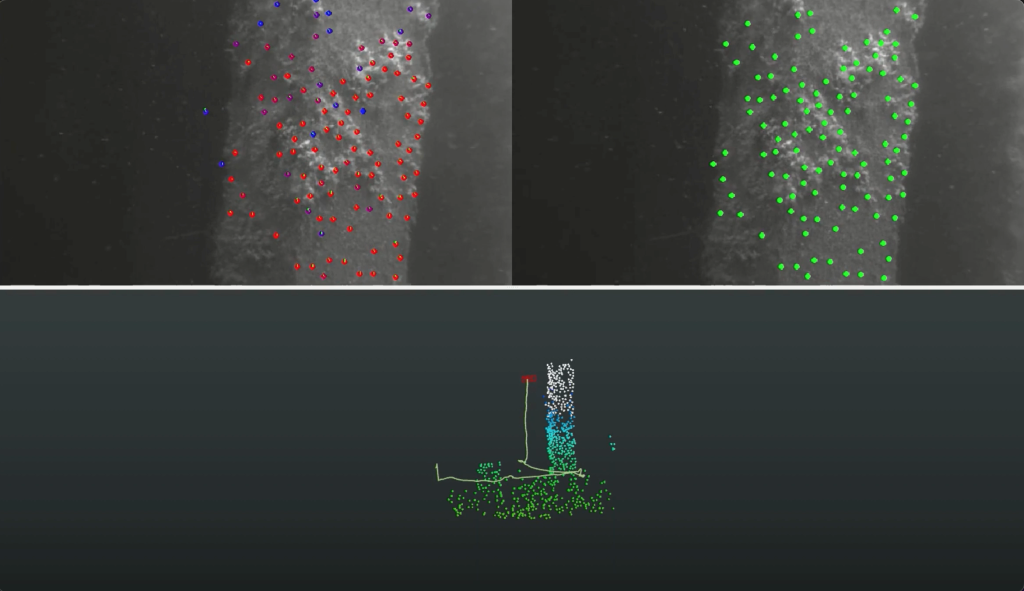

UVision have integrated cm precise GNSS positioning capabilities into their solution, providing accurate positioning of the UScanner underwater. Position data can be streamed in real-time to the scanner where it is combined with image data. The resulting 3D models accurately positioned in the global coordinate system.

Global positioning also means that the models themselves are even more accurate and robust, especially over large areas. With this level of accuracy it is possible to compare models and detect changes happening over time. In addition, it makes it easier to produce models in steps and present them as a whole joined structure.

Positioning data can be read into to the UController on the operator laptop in real-time from any positioning system (eg USBL, RTK) supporting NMEA GGA format, or we can make a specific adaptation. UVision also offer a pre-integrated RTK receiver for the pole mounted option.

Why Use a Visual 3D Scanner for Offshore Wind Turbine Inspection?

Photorealistic Detailing

Visual 3D models capture the intricate details of underwater structures in high resolution, providing a comprehensive view that aids in identifying defects or damage with unparalleled clarity. This photorealistic detailing ensures no critical issues are overlooked.

Millimeter Precision

These models offer precise measurements up to the millimeter, enabling accurate assessments of structural integrity and wear. This level of precision is crucial for planning maintenance, repairs, and ensuring the long-term safety and efficiency of offshore wind turbines.

Cost-Effective Monitoring

With the ability to generate detailed and accurate models quickly, visual 3D scanning reduces the need for frequent diver deployments, cutting down on inspection costs and time. This efficiency makes it a cost-effective solution for ongoing infrastructure monitoring.

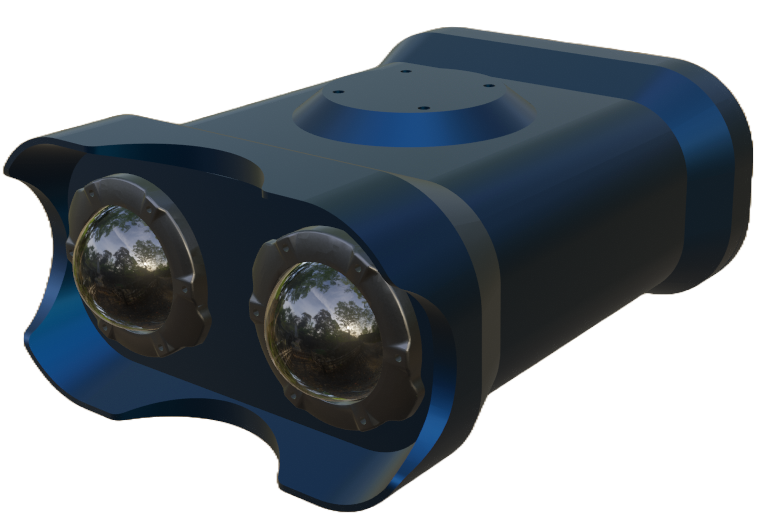

Underwater 3D Scanner

Starting at €13.900 ex.VAT

The UVision 3D Scanner is a cutting-edge device that seamlessly combines high-quality still images and positioning data for efficient point cloud generation and photogrammetry.

The global shutter stereo camera captures all pixels at the same moment – as opposed to rolling shutter which reads pixels sequentially – securing the most accurate image is captured. The dome ports minimise distortion at the periphery of the field of view, maximising image quality.

The device is small and light giving it various mounting options. The aluminum casing is corrosion resistant and designed for 300m depth.